Engineering

Driven to Improve in Everything We Do

Tuff Torq has one of the best engineering teams in the world focused on developing and manufacturing the very best hydrostatic and mechanical drive systems for the lawn, agriculture, construction, industrial, off-highway and marine industries. Our team is separated into specific departments that all work together to produce innovative and effective drive solutions for our OEM customers and their consumers. Take a look below at the different areas where Tuff Torq’s world class engineering team is focused.

To learn more, watch our brief video about Tuff Torq’s engineering team.

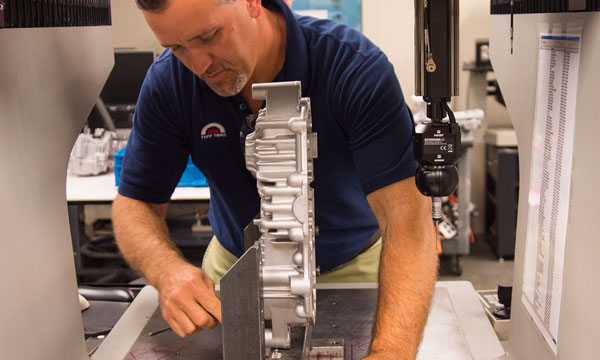

Quality Assurance and Product Testing

Tuff Torq has made a huge investment in testing facilities and quality assurance staff and equipment for one purpose—to insure that our products stand up to the Tuff Torq name. There is a reason that almost every OEM on the planet chooses Tuff Torq to drive their best products. We take that trust and expectation very seriously.

Here are just a few of the many QA investments that Tuff Torq has made:

- Dedicated team of engineers to focus solely on Quality Assurance and Product Testing.

- Extensive testing laboratory for product evaluation that includes dynamometers, dynamic drive testing and product load limitations. Tuff Torq just added a second lab this year to meet our needs for testing as we continue to grow.

- State-of-the-art Quality Assurance labs with professional production auditing, capabilities to measure product machining tolerances at the microscopic level and custom-built positive pressure and leakage testing equipment.

- On-campus field testing track for riding and zero-turn mowers. This track provides continuous testing on several different grades and in all weather conditions. We can run up to three shifts of staff to keep test equipment running non-stop in order to find out what the weaknesses of our product are in extreme real-world situations.

- Brand new off-highway field testing facility. Tuff Torq has developed a massive field testing facilities to support our new lines of off-highway recreational and utility vehicle drive systems. This 80-acre facility gives us the ability to “torture test” our products in rocky, sandy, muddy, wet and hard surface situations. This new field testing facility has been designed and engineered with the input of some of the top off-highway vehicle manufacturers in the world.

Research and Development

Tuff Torq is known as a global leader in developing new and unique product solutions for the hydrostatic, hydraulic and mechanical drive system markets. This leadership has driven us to continue to strive to develop the best technologies to meet our OEM customer’s needs while building on the quality reputation for which Tuff Torq is known.

Here are a few of the ways that Tuff Torq has invested in developing the best products for the future:

- International team of research and development engineers in the United States and Japan, committed to researching the needs of the market today and in the future.

- Development software custom built to allow Tuff Torq to prototype, design and test product designs in a virtual environment in order to quickly and efficiently create and refine product ideas while saving cost and time.

- In-house machining and tooling facilities allow us to build small-run prototypes for testing and OEM evaluation.

- Dynamic manufacturing strategy, which allows Tuff Torq to respond quickly to mid-cycle design changes and new product development.

- Dedicated sales and marketing department to monitor industry trends and competitive analysis helps Tuff Torq to recognize emerging market opportunities.

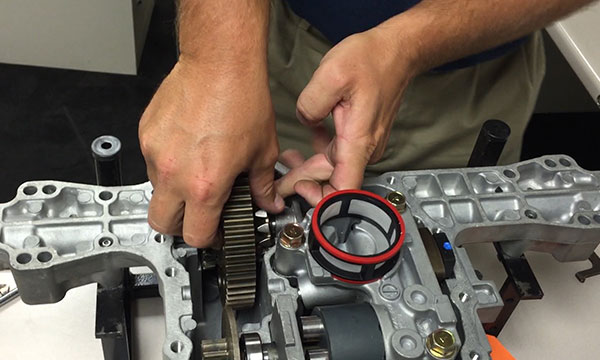

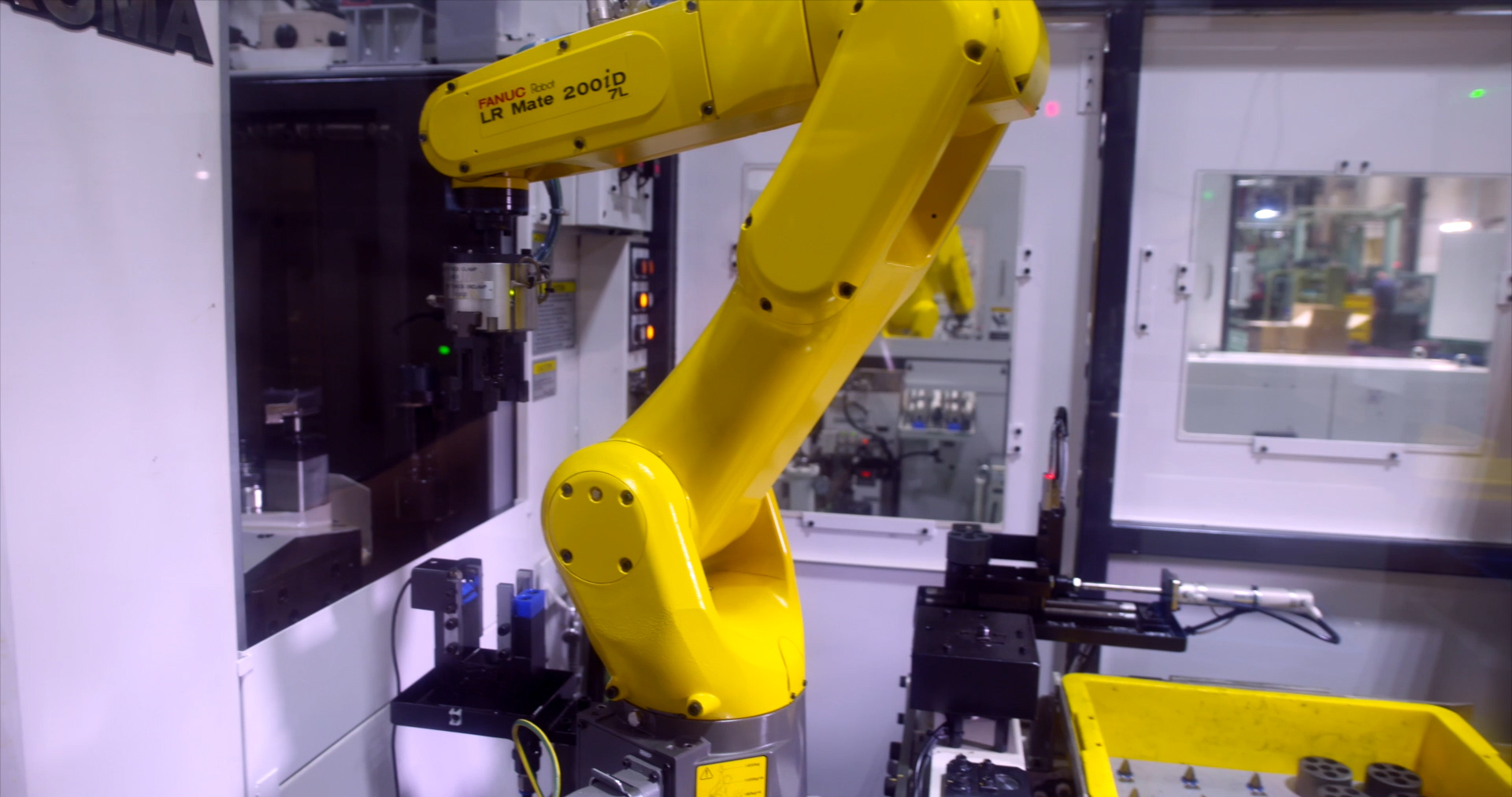

Production Engineering

Tuff Torq’s production facility is second to none. Our team of production engineers has created a manufacturing system that is both responsive to the changes in our product lines and diversity of products—while also being rock-solid in the consistency of the products coming off the line and going to our customers. The spirit of harmony and strive to always improve is demonstrated perfectly in the development of our product manufacturing process. Having the perfect blend of manufacturing automation and experienced human oversight gives Tuff Torq the winning edge in consistent product quality.

Service Engineering

The first part of an effective service team is building the best product we can. Tuff Torq believes that exceptional service starts from the first day of product design. We try to make service part of everything we do at Tuff Torq. Our parts and service team works very hard to support both our existing products in the field and the new products we are designing for tomorrow. With professional team training and the support materials we are producing for our OEM customers, we hope to create an easily accessible resource library to make our products easy to use and simple to service.